Technical Specification

Exceptional Durability

The chemical composition of Firestone’s RubberCover™ EPDM membrane (high proportion of carbon black (> 25%) and saturated carbon chains) and the fact that it is vulcanized (strongly cross-linked chains) mean that the membrane benefits from an unmatched resistance to UV,ozone, micro-organisms and extreme weather conditions.

Unlike some thermoplastic membranes, the membrane does not contain any plasticizers or antioxidants likely to migrate or degrade and cause the membrane to age prematurely.

Tests conducted on the Firestone RubberCover™ EPDM membrane and the observations made on membranes exposed to several years’ worth of actual weather conditions (exposure to rain, UV, ozone, heat, thermal variations and microorganisms etc.) have shown that under normal exposure in western Europe and when fitted according to good engineering practice the Firestone RubberCover™ EPDM membrane has a service life of more than 50 years, without any apparent sign of ageing such as cracks, crazing and bleaching etc.

The EMMA test (Equatorial Mount with Mirrors for Acceleration) consists of concentrating sunlight under a tropical climate by using mirrors. The Firestone RubberCover™ EPDM membranes were exposed to more than 2,000,000 Langley under this test, without sustaining any cracking or crazing.

Standard Tests:

| Standard | 1.14mm | |

|---|---|---|

| Ozone resistance: | EN 14575 | Compliant |

| Durability - UV Ageing: | EN 1297 | Compliant |

SKZ study:

In 2004, a study was conducted by the German Institute of Synthetic Materials (SKZ) to determine the minimum service life of EPDM rubber membranes. Thirty-nine samples of EPDM membranes were taken from roofs in Western Europe that were 20-30 years old. Over a period of 2 years, these samples were subjected to tests for artificial ageing at high temperatures in laboratory conditions.

The results of the study are as follows:

- All the roofs visited where in a perfect condition and operating as intended.

- No external signs of ageing were noted (crazing or cracking)

- None of the elongation at break values obtained were less than 300%.

- Each sample was artificially aged up to the lower threshold of 150% elongation to obtain the values for remaining life span. All results obtained have exceeded the 70-year life span.

Study conclusions:

The life span of EPDM membranes is clearly evaluated at over 50 years in normal west European climate conditions.

High elasticity and tensile strength

Given the significant level of cross-linking in its carbon chains, the RubberCover™ EPDM membrane can be elongated over 300% in all directions and return to its initial form afterwards. This high elasticity allows the RubberCover™ membrane to accommodate any substrate irregularities without its physical properties being affected.

Standard Tests:

| Standard | 1.14mm | Unit | |

|---|---|---|---|

| Tensile Strength: | EN 12311-2 (B) | ≥ 7 | N/mm² |

| Elongation at break: | EN 12311-2 (B) | ≥ 300 | % |

Highly flexible, even at low temperatures

Firestone’s RubberCover™ EPDM membrane is highly flexible even at low temperatures down to -45°C. Installation is therefore easily facilitated as it adapts to irregular shapes of the substrate, whatever the outside temperature.

When mechanically stressed at low temperatures, the membrane retains all its flexibility and its characteristics remain unchanged. Please note that application at low temperatures requires certain precautions to be taken to achieve a high-quality result.

Standard Test:

| Standard | 1.14mm | Unit | |

|---|---|---|---|

| Flexible, even at low temperature: | EN 495-5 | ≥ -45 | °C |

High puncture resistance

In view of its highly flexible and elastic nature, Firestone RubberCover™ EPDM membrane also provides excellent puncture resistance. This is an especially important characteristic in withstanding the mechanical stresses which the membrane sustains during installation and commissioning or under climatic stresses such as hail.

Consequently, the membrane allows for long term water-tightness to be guaranteed.

In France, waterproof surfaces benefit from a performance classification known as "F.I.T. Classification" which measures fatigue, resistance to puncture and resistance to heat. The Firestone RubberCover™ EPDM membrane: obtained F.I.T. classification: F5 I5 T4.

Standard Tests:

| Standard | 1.14mm | Unit | |

|---|---|---|---|

| Resistance to static puncture: | EN 12730 | ≥ 20 | kg |

| ≥ 1700 | mm |

High resistance to hydrostatic pressures

The Firestone RubberCover™ EPDM membrane has an unmatched resistance to hydrostatic pressure. Firestone has conducted laboratory pressure tests which have shown that the membrane can withstand pressure up to 35 kg/cm² (equivalent to 350 m water column or 3.4 MPa) without causing a permeability defect in the membrane.

These tests conducted according to EN 1928 standard showed that when a pressure is applied equivalent to 40 m water column (400 kPa), the Firestone RubberCover™ EPDM membrane and its seams remain impermeable.

Although Firestone recommends an incline allowing adequate runoff, stagnant water does not contribute to an acceleration in the ageing process of the membrane or the seam.

| Standard | 1.14mm + seams | |

|---|---|---|

| Water tightness under water pressure: | EN 1928 | Compliant |

Fire resistance

Firestone's Low-Slope-Fire-Retardant (LSFR) EPDM compound membranes have been tested for resistance to external exposure to fire:

| Standard | 1.14mm + Polyiso Insulation + VCL & Plywood | |

|---|---|---|

| External fire resistance | BS476-3:2004 | Ext. F.AC |

| Standard | 1.14mm with 50mm stone ballast covering | |

|---|---|---|

| External fire resistance | BS476-3:2004 | Ext. F.AA (deemed to achieve) |

In accordance with The Building Regulations Part B (England & Wales), Building Regulations (Northern Ireland) Technical Booklet E, and Building Regulations Part B4 (Republic of Ireland) there are no restrictions on the use of flat roof coverings designated AA, AB or AC.

Similarly, The Building (Scotland) Regulations classifies roof coverings with a designation AA, AB or AC as 'Low Vulnerability'.

Consult Firestone Technical Services for the external fire resistance performance for other roof construction types.

Stable chemical composition

As a result of its chemical composition (saturated highly cross-linked carbon chains, without plasticizers) and its production method (heat vulcanized), the Firestone RubberCover™ EPDM membrane is considered an inert material as its chemical composition is very stable over time (when in contact with authorized products).

A stable chemical composition is vital in guaranteeing the mechanical properties of the membrane on a long-term basis. Chemical damage related to climate conditions such as acid rain, have no negative impact on the membrane.

Unlike some thermoplastic membranes, no reduction in density has been noted following loss of membrane components.

Collection of rainwater

Owing to its very stable chemical composition, Firestone's RubberCover™ EPDM membrane does not release components when in contact with water.

Physical tests have demonstrated that the Firestone RubberCover™ membrane and its assembly system are compatible with the collection of rainwater.

It is therefore possible to reuse the water collected as domestic water. Note that provision must be made for a filtering system for dusty residues.

Environmental suitability

Numerous studies have shown the inherent advantages of EPDM membranes with regard to environmental suitability in providing an optimum solution for "durable" waterproof roofing systems.

Reduced environmental impact and environmentally-sound membrane.

- The environmental impact of a membrane expressed in GWP (global warming potential) or equivalent CO2 takes place predominantly in its production and disposal. The exceptional durability of the Firestone RubberCover™ EPDM membrane compared to other waterproof membranes, along with its numerous opportunities for recycling and easy repairs, means that its life span is extended. The membrane is recycled into rubber by-products or devulcanized to be reintroduced into the production chain. The environmental impact of the EPDM membranes is therefore significantly reduced.

GreenTeam¹ Inc. conducted a Life Cycle study analyzing the impact on climate, atmosphere, water, and the toxicity of various membranes including modified bitumen.

¹ GreenTeam Inc. is a group of strategic consultants specialising in issues concerning the construction industry and more specifically sustainable construction and environmental matters.

The results show that the environmental impact of EPDM membranes is less than that of SBS, PVC and TPO membranes.

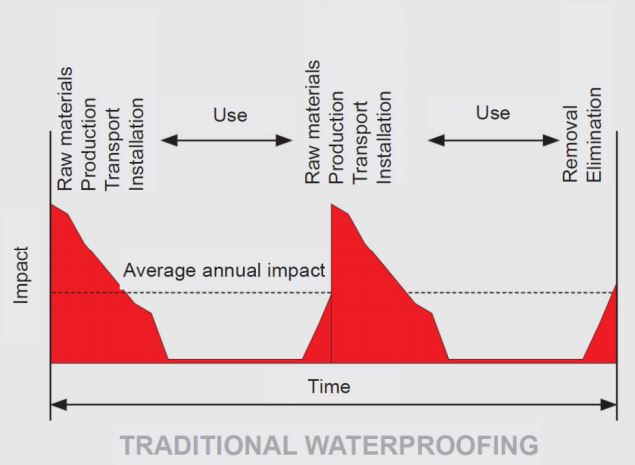

The diagrams below represent the difference in environmental impact between two waterproofing membranes. The first diagram shows the environmental impact of a traditional waterproofing membrane.

Due to their larger mass and shorter life span, bitumen membranes have a more significant environmental impact (GWP) during production, transportation, and installation.

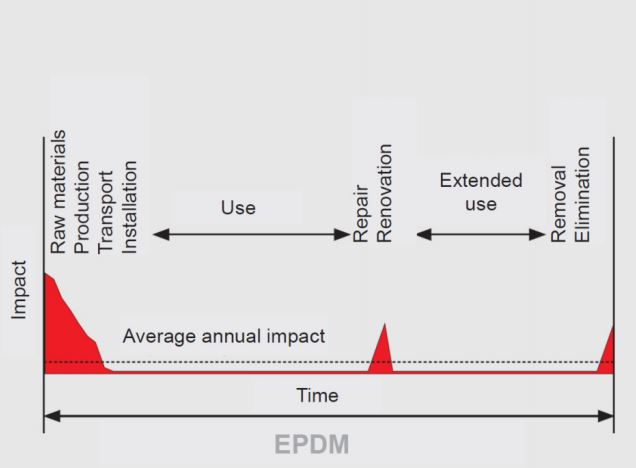

The second diagram shows the environmental impact of an EPDM membrane.

EPDM membranes have a longer life span and as they are easy to repair, meaning that complete renovation of the roof which is generally high in CO2 emissions can be delayed.

A lower average annual environmental impact can be noted on this second graph compared to the first.

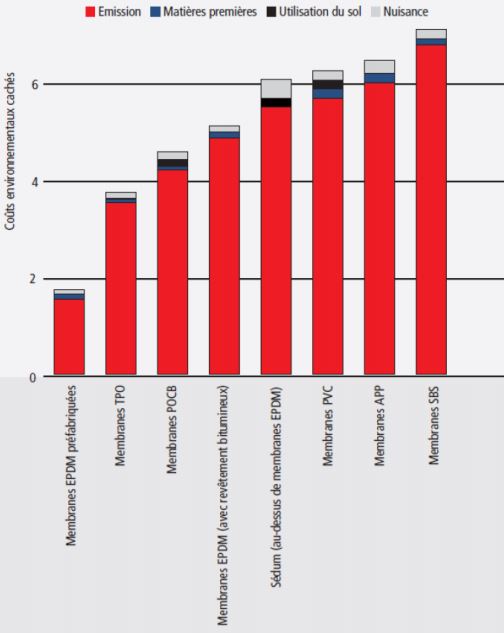

The Dutch institute for building biology and ecology (NIBE) publishes an annual comparative report on a selection of construction materials and their respective environmental impacts. One of these reports evaluated the various waterproofing membranes over a period of 75 years. Two important aspects were analyzed: building costs (installation costs per m² ) and hidden environmental costs (emissions, raw materials, etc.).

Eight waterproofing roofing products were included in the study. The comparison shows that EPDM is the most ecologically sound product.

- For northern European countries such as UK, France, Belgium, etc., the black colour of the membrane allows for a reduction in heating costs during heating periods, thereby reducing CO2 emissions.

- The Firestone RubberCover™ membrane is chemically inert, nontoxic, without any carcinogenic ingredients, therefore the quality of water in contact with the Firestone RubberCover™ EPDM membrane complies with environmental standards for surface water and does not contain the presents of abnormal bacteria. The water can be reused as domestic water.

- Out of concern for the environmental and ecological impact of the Firestone RubberCover™ EPDM membrane, Firestone developed a waterproofing system that is compatible with photovoltaic systems. Given its substantial durability over time, the use of EPDM means that complete renovation works can be delayed which would be costly when relating to a photovoltaic system.

Root penetration resistance (garden roof)

Garden roofs consisting of vegetation planted above a waterproof membrane have become a common feature in recent years.

Firestone’s RubberCover™ EPDM membrane has successfully passed various root penetration resistance tests (DIN 4062, CEN/TS 14416: 2005, FLL & EN 13948).

The Firestone RubberCover™ EPDM membrane is therefore compatible with extensive green roofing systems, using sedum which requires little maintenance.

Nevertheless, it is necessary to remain extremely careful about certain plants which develop particularly aggressive root systems (a non-exhaustive list of plants which develop aggressive root systems can be obtained on request or from the website www.fbb.de). When confronted with plants which develop aggressive root systems or rhizomes, a protection barrier must be implemented to protect the waterproofing system. Further information on garden roof systems is available on the Firestone website (http://www.firestonebpe.com).

Standard Test:

| Standard | 1.14mm | |

|---|---|---|

| Resistance to root penetration | EN 13948 | Compliant |

Review

I recently had a double-length garage roof replaced by Ben and his team and would like to praise them for their work. They worked straight through without a break or lunch for five hours and cleared up thoroughly afterwards. I would definitely recommend them.

Maureen Harrison

Broad Oak Lane, Penwortham

Registered in England | Company Number: 08265364